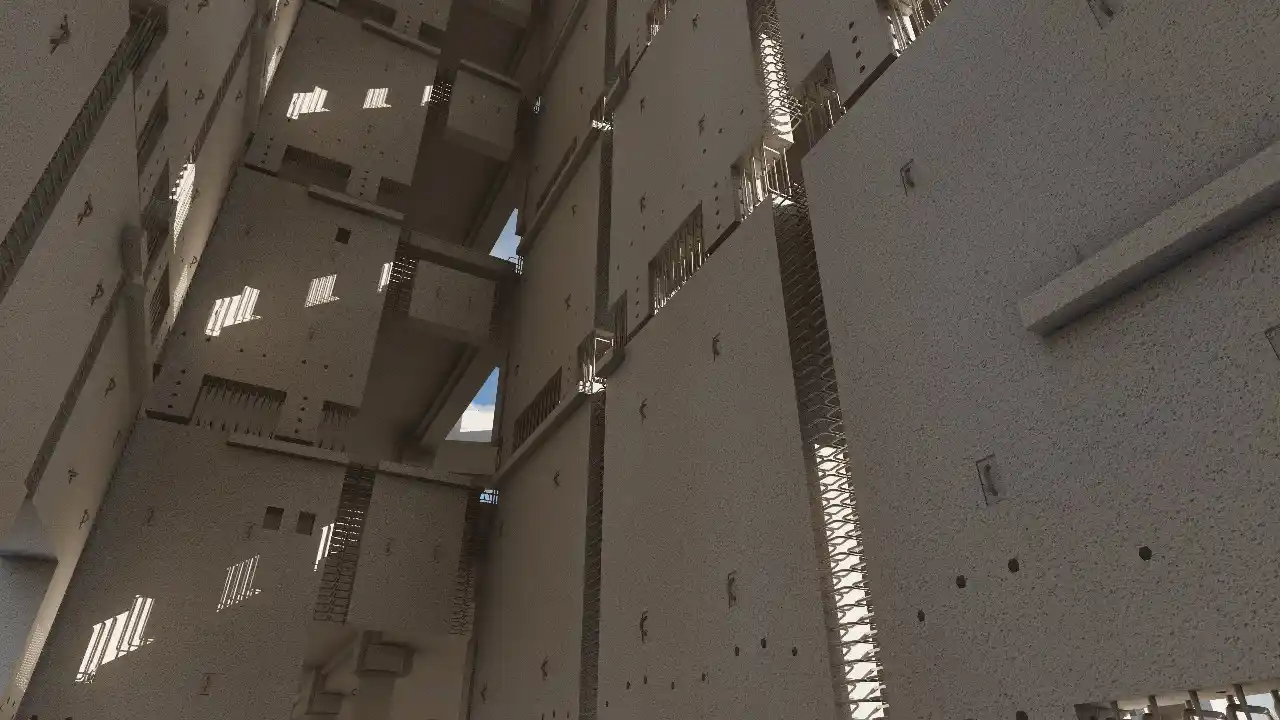

BIM technology has become essential in achieving quality and precision in precast concrete design. One of the biggest challenges in precast projects is ensuring that each piece is produced and installed according to strict specifications. BIM aids in overcoming these challenges by allowing designers to create highly detailed, parametrically controlled models. These models can include data on dimensions, material specifications, reinforcement details, and installation sequences, making it easier to detect any clashes or design issues before production begins. This proactive approach enables manufacturers to deliver high-quality, accurate precast components while significantly reducing rework and associated costs.

Key Benefits:

Greater precision in modeling and production.

Early clash detection reduces rework and delays.

Leave A Comment